Shopping Cart

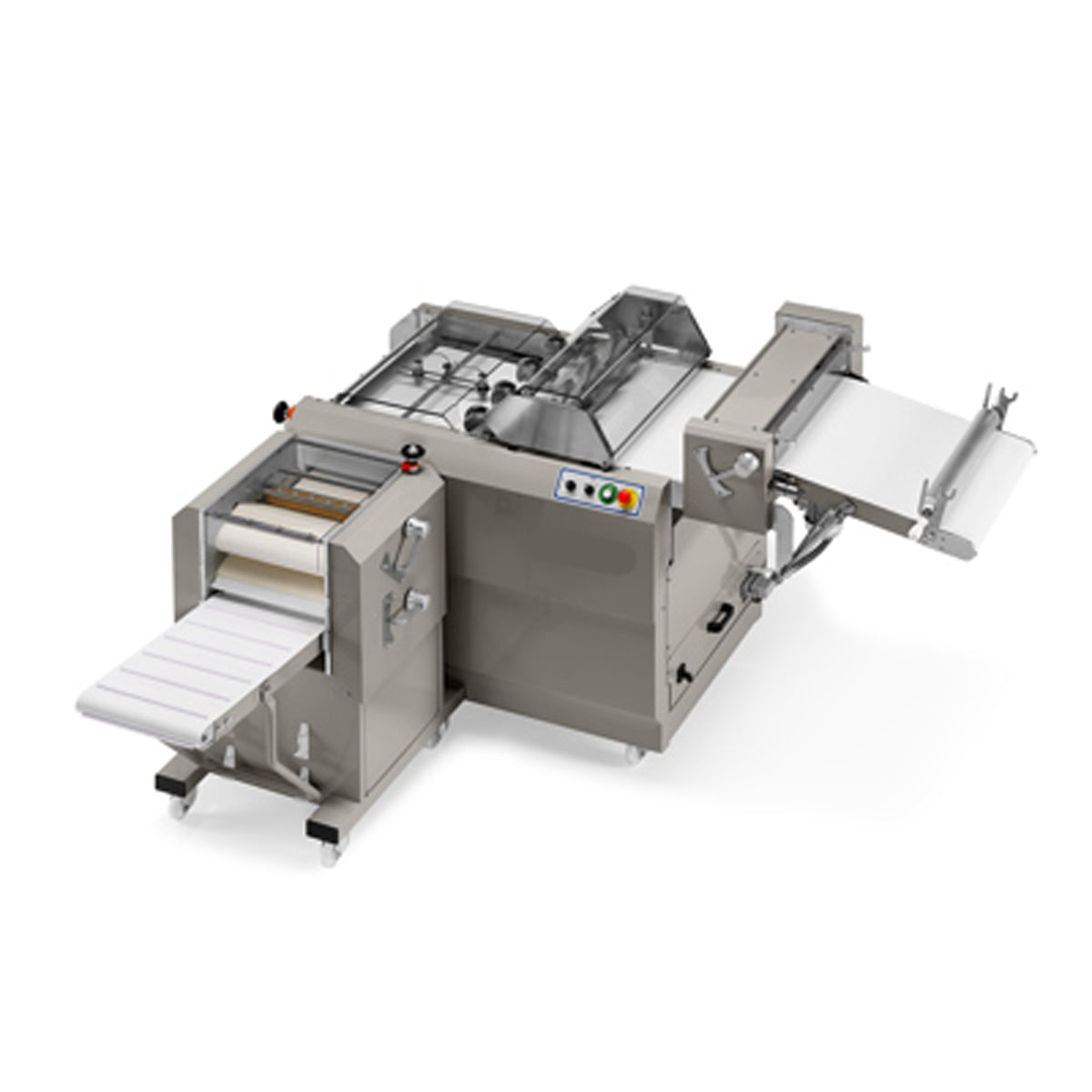

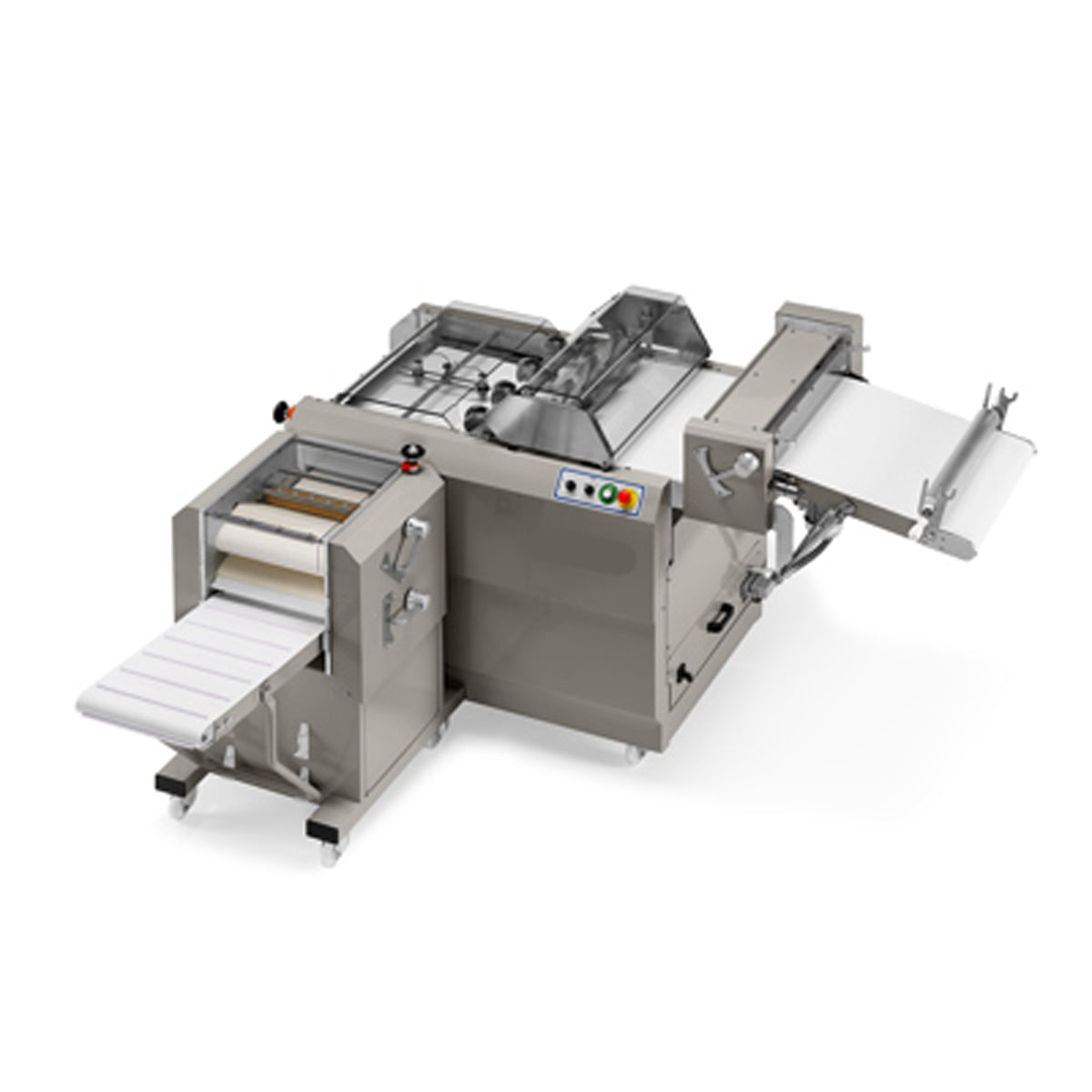

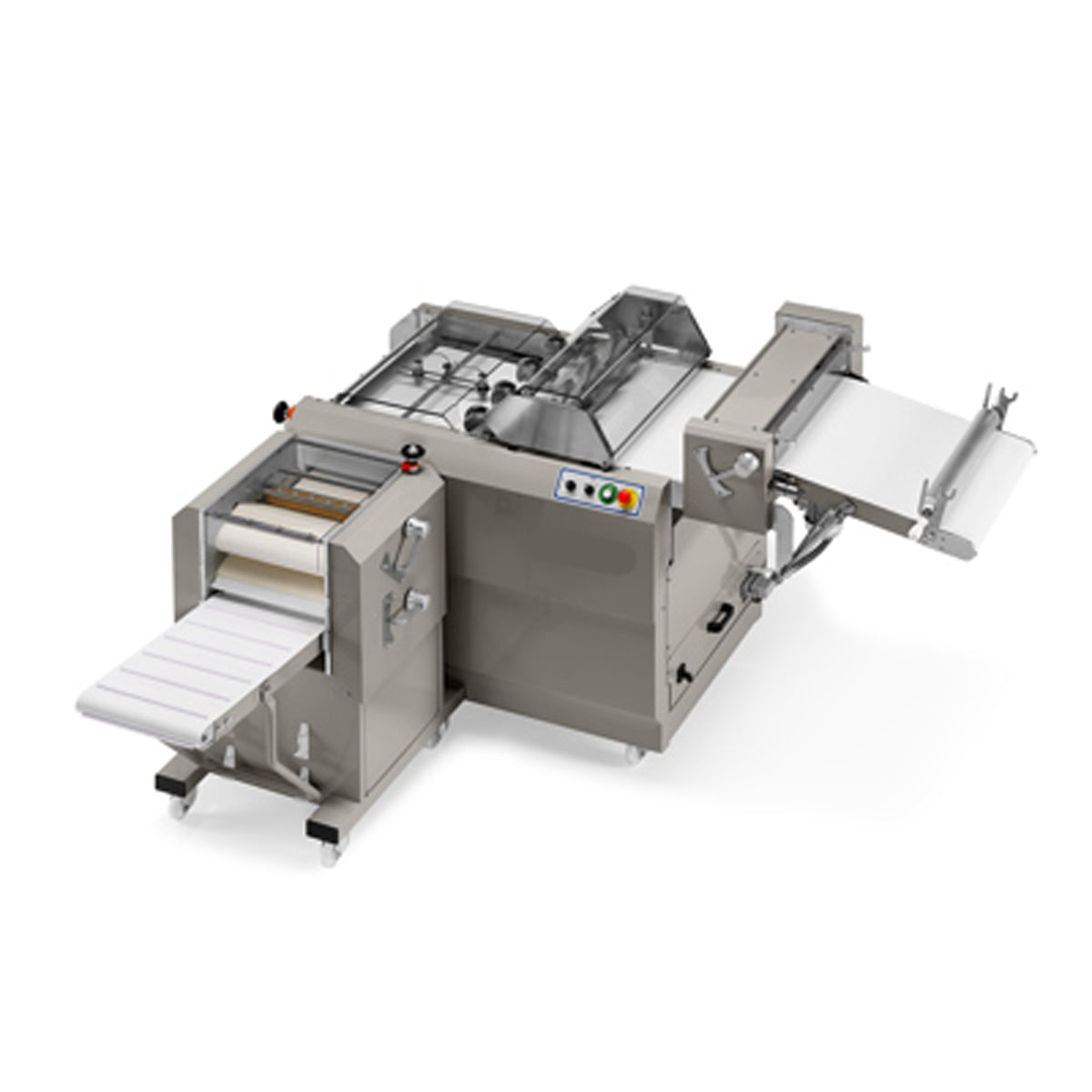

Croissant group 3000-6000 pieces per hour

- Sku: CS0204

Regular price

€25.425,00

Price on demand

850

Croissant group 3000-6000 pieces per hour

Combination: 3000 Pieces

Shipping times may vary depending on the working period (August and Christmas holidays) and stock availability.

Buy in complete convenience with operational rental by Grenke dividing the cost up to 60 months. Find out more

12 month warranty.

After-sales telephone assistance.